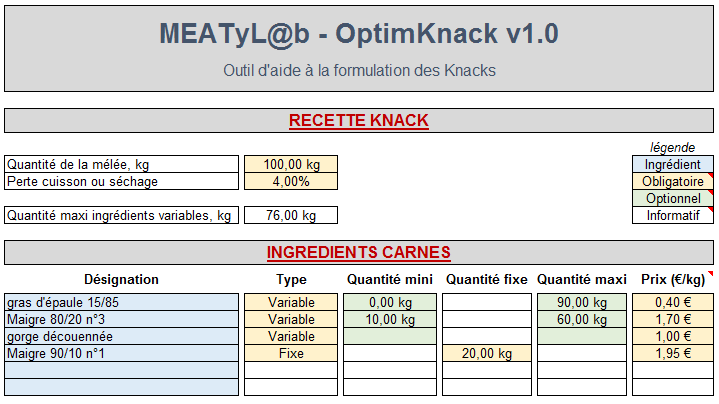

Composition of a knack mixture

In the composition, there are two types of ingredient to which we will be able to assign min, max or fixed quantity constraints:

- meat: shoulder fat 15/85 (between 0 and 90 kg), lean 80/20 No.3 (between 10 and 60 kg), rindless and lean jowl 90/10 n°1 (20 kg fixed),

- non-meat: a binder 2017/4382 from Solina (1.38 kg fixed), a type 1 seasoning from Solina (2.70 kg fixed), water/ice type 1 and sodium nitrite salt 0.6%.

The optimised recipe: products and cost price

From the elements provided, the maths will do its job and the tool will calculate different recipe possibilities, as well as the associated cost price, whilst considering the food properties to be adhered to before and after cooking (lipids, nitrites, sugars, sodium, etc.).

In the above example, we obtain the following result:

- cost of products: €77.12 per 100 kg

- shoulder fat 15/85: 7.94 kg

- lean 80/20 n°3: 29.68 kg

- rindless jowl: 21.24 kg

- lean 90/10 n°1: 0 kg

- binder 2017/4382: 1.38 kg

- type 1 seasoning: 2.70 kg

- water/ice type 1: 35.56 kg

- sodium nitrite salt 0.6%: 1.50 kg

The tool then deduces nutritional information after cooking:

- humidity: 62.40%

- lipids: 29.90%

- saturated fatty acids: 8.43%

- carbohydrates: 0.13%

- sugar: 1.17%

- protein: 9.57%

- collagen: 1.29%

- sodium: 0.83%

It is the same for engineers who wish to automate nutritional labels or improve a nutri-score, mathematics has helped the butcher-pork butcher-caterer here to determine the best combination for knack recipes quickly in relation to his available raw material, all at minimal cost.

Conclusion

Don’t be afraid of maths anymore! Digital tools, computing power and applied mathematics are superb tools for saving time on a daily basis, whether you are industrialists or craftsmen. You can finally focus on your business and provide consumers with qualitative information about your product to reassure them, whilst controlling your cost price.

Together, let’s spend time tasting!

Julien Jourdan