Optimisation to improve performance

System performance is often reduced to dynamic performance, which is optimised by the automation engineer, whereas global performance also relies on sizing components and wisely choosing some of the static settings, outside the scope of regulation parameters and real-time algorithms.

For instance, robotic arm performance obviously depends on control calibration, initially the results are determined by the kind of electrical motor chosen.

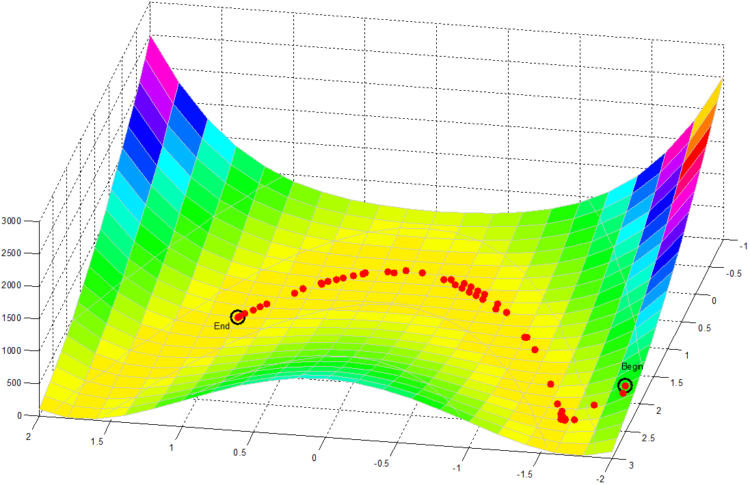

In order to find the best settings to optimise a system, designers often have to solve a dilemma between antagonist criteria, like speed and accuracy. Reaching the solution can be very difficult and require several simulations, and the more complex the system is, the slower the simulations will be.