For 20 years, we have carried out many projects for our customers, and we finally have the opportunity to present you with an illustration of our expertise during our trade shows.

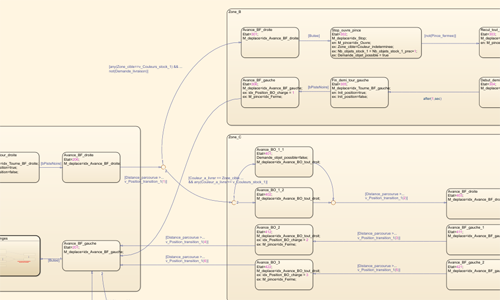

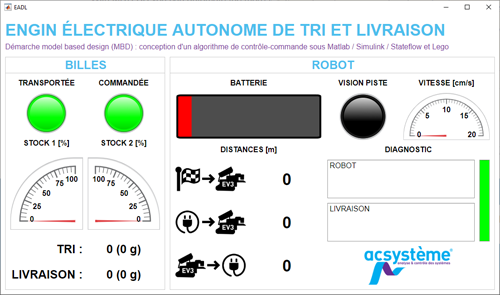

Indeed, this electronic, autonomous delivery device demonstrator is a perfect illustration of the model-based design (model-based design – MBD) approach used in command-control algorithm design projects. Here we worked in the Matlab/Simulink/Stateflow environment from Mathworks® and with the Lego Mindstorms platform from Lego®.

Model and algorithms

In order to highlight our expertise in modelling and designing command-control algorithms, we have developed an electric robot model with automatic guidance. This autonomous machine is responsible for delivering and sorting coloured balls from a dispenser to dedicated storage locations, whilst managing its travel autonomy depending on the capacity of its battery.

The elements of the model

This model is based physically on several elements:

- a movement space made up of Lego® elements marking out its area of action and a line on the ground enabling the robot to locate itself,

- an autonomous robot which recovers a ball, analyses its colour then sends it to the stock corresponding to this colour by following the black track on the ground,

- a dispenser that randomly delivers a coloured ball each time the robot approaches it,

- a remote control that allows a user to interact with the robot (request delivery of a coloured ball, start, stop, etc.),

- a screen that displays in real time the information sent by the robot (colour of the ball picked up, consideration of a user request, battery status, diagnostics, etc.).

The platform for coding

With the Lego Mindstorms environment, we quickly and simply have a platform to embed our code: an EV3 programmable brick, a colour sensor, an intensity sensor, a stop sensor, a Wi-Fi transmitter/receiver, an infrared transmitter/receiver, and actuators to move the robot forwards and drive the gripper.