Model-Based Design (MBD)

Onboard solutions are expanding at stupendous speed in recet years and in every sector: telephony, aeronautics, automotive… With them, the need to develop faster and faster is emerging, while high quality is still required.

Onboard solutions are expanding at stupendous speed in recet years and in every sector: telephony, aeronautics, automotive… With them, the need to develop faster and faster is emerging, while high quality is still required.

In the software world, model-based design has appeared as the best way to meet cost, quality and time requirements.

A model is a set of equations, laws or rules describing a system behavior, more or less accurately according to the kind of phenomenon studied. Physical prototypes can be replaced by virtual model, adjusted to an experimental database to be as close as possible to reality and simulated to analyze system behavior in any case of scenario.

During conception, these models will also be useful to try new features (like choosing the motor type of a hybrid vehicle).

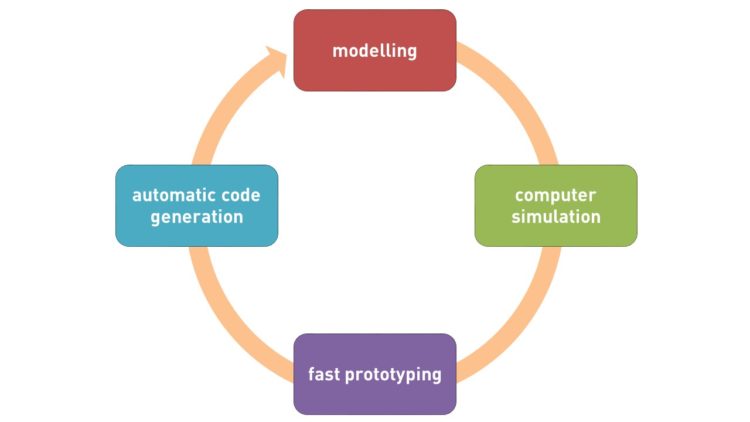

The Model Based Design approach saves time during the designing phase of onboard software by testing each feature when it is developed. From the drafting of the specifications, it is possible to evaluate the feasibility of the customer’s requirements. Each step of the development benefits from this methods thanks to quick prototyping and modular solutions for simulation (hardware in the loop software and model in the loop).

The Model Based design approach eases system sizing by showing performance limits in the early phases of development.

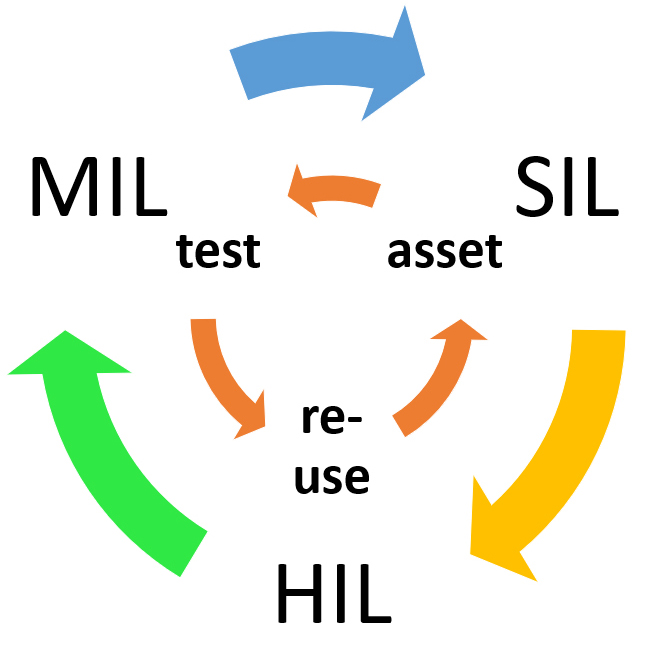

Hardware in the loop (HIL), Software in the loop (SIL) and Model in the loop (MIL) solutions allow you to validate your developed solutions with simulations of real situations. Their use accelerates deisn and enhances quality mastery, while reducing the appeal to real prototypes and physical tests.

Here is a short description of an “in the loop” simulation solution, in chronological order:

Those phases help to test a maximum of scenarios in early development in order to reduce the average cost of tests. Let’s take the regulation loop that cools electrical vehicle organs as an example, the principle is to reduce the calculator’s temperature thanks to a water circuit. The first step is to model the system: control loop, pump, electrical elements… Then we develop a control law to start the pump when the system exceeds a threshold and we test it on the model (MIL). According to results, we adapt the regulation to system reactivity and specifications. Once this is done, we generate the code for the control law (C/C++) just before testing it with the model (SIL). When the previous step has been validated, code is implemented into a real calculator connected to a physical simulator to check if performance still meets the requirements (HIL).

“Configure as a UAV”, robotise, automate, make autonomous… so many terms for your new project so that your system moves independently without human intervention.

The field that relates to this invention is the control of electrical powertrains used for electrical and hybrid vehicles.